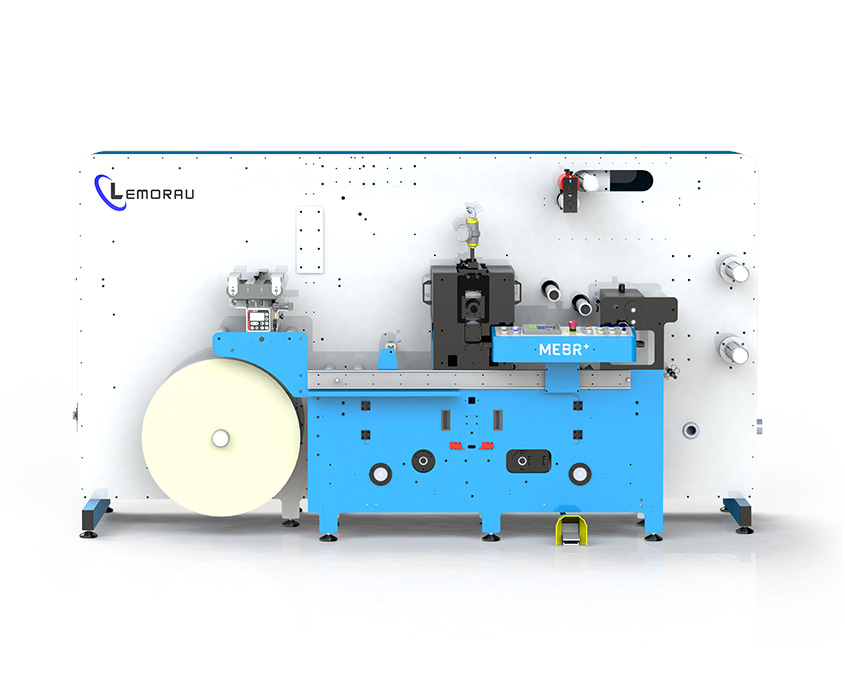

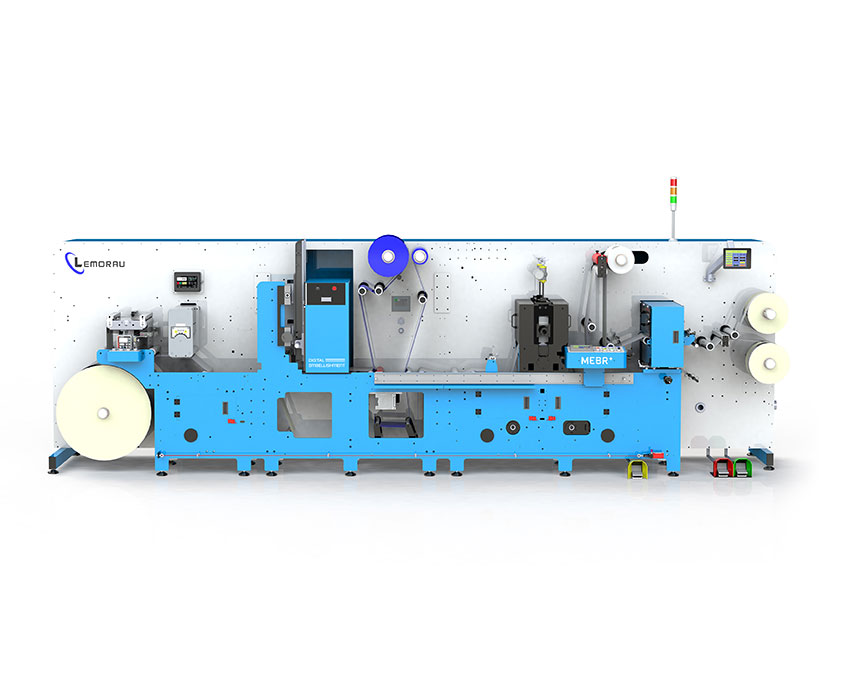

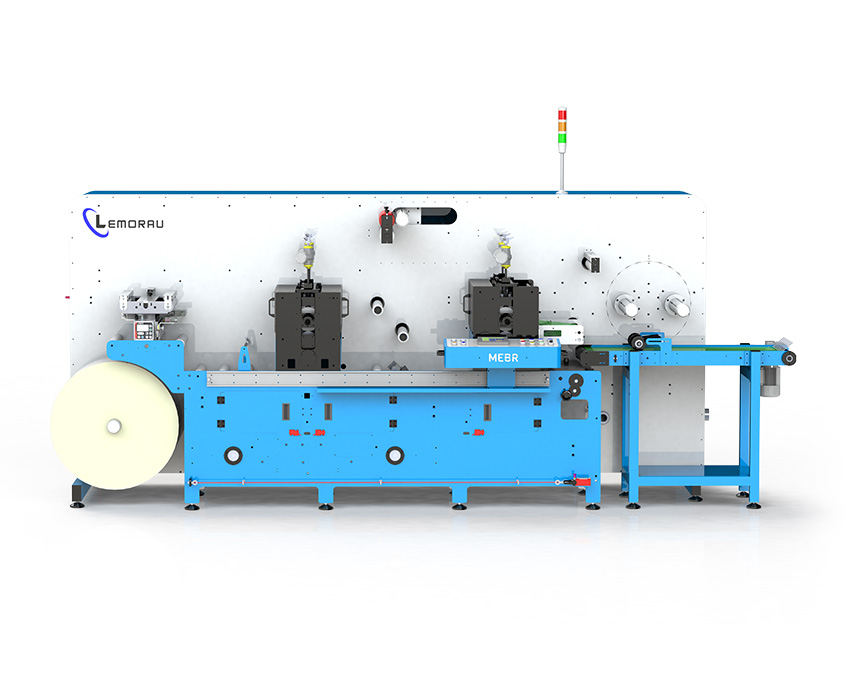

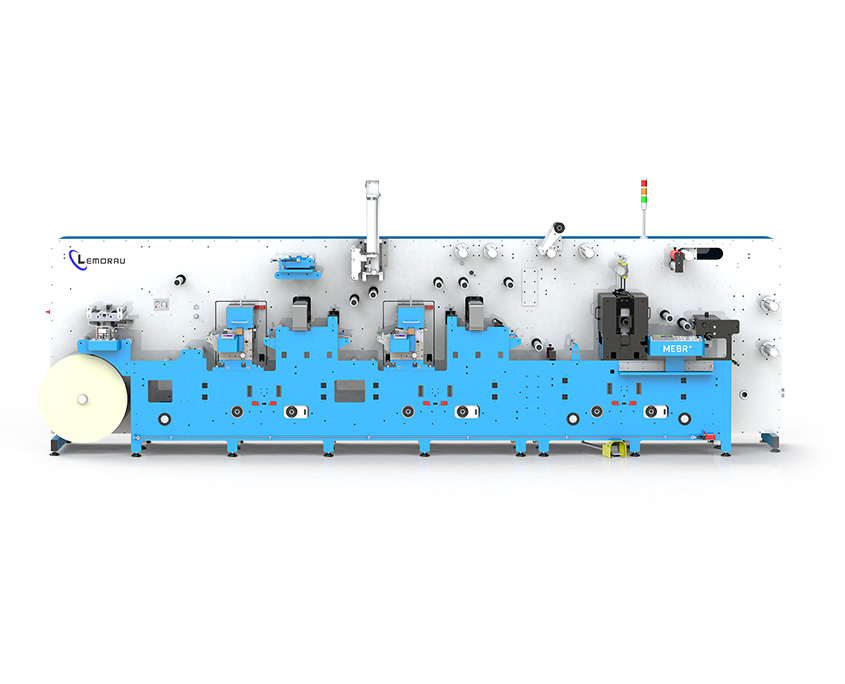

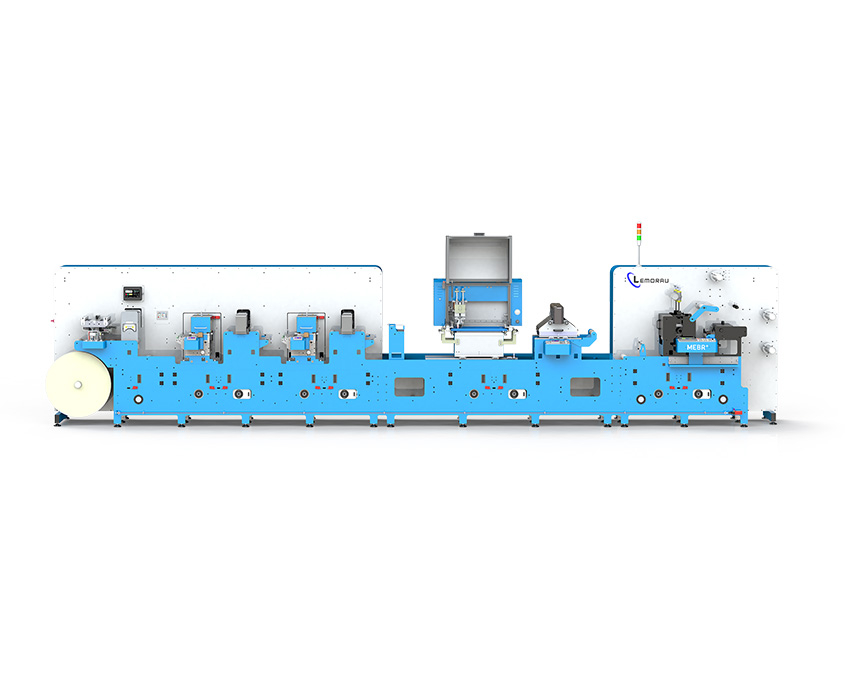

Lemorau MEBR+

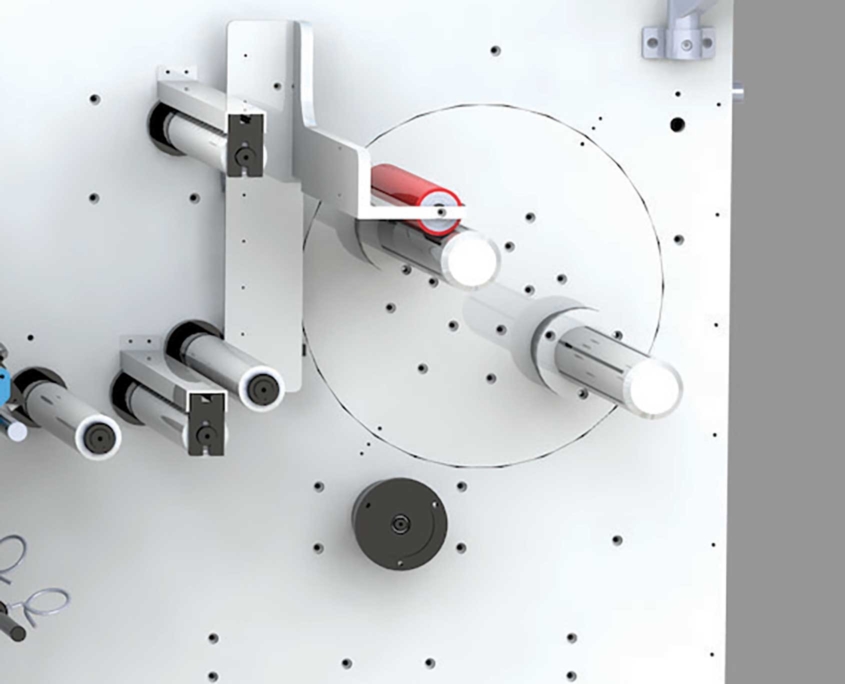

Lemorau MEBR+ is a modular digital finishing machine designed for ultimate flexibility. Add or upgrade modules to match your production needs. The die-cutting unit works in semi-rotary for short runs and full rotary for high-speed, long runs, all while maintaining precise registration. Advanced servo technology and a servo-driven compensator system ensure superior web tension control and consistent, high-quality results.

STANDARD FEATURES

- Max. rotary speed for blank labels: 200 m/min. (656 ft/min.)

- Max. rotary speed die cutting to register: 120 m/min. (394 ft/min.)

- Max. semi-rotary speed die cutting to register: 40 m/min. (131 ft/min.) with intelligent speed limit according to repeat

- Web width 250, 330, 400, 450 mm, other sizes (10, 13, 16, 18”, other sizes)

- Electronic Counter (Labels/ Meters/ Rolls/ Total meters and labels Counter / Information of current rolls diameters)

- Job memory for easy and quick job set ups

- Paper and matrix break detection

- QRC (Quick Remote Connection)- For fast and easy access to the machine remotely

- Automatic web tension control system by servo motors – Constant and Taper tension

- Smart Gap – Software compatible with all digital printers

- Multi language HMI touch screen

- Electrical supply according to country/customer request (no need of transformers)

- CE conformity certificated, user manual and electrical scheme

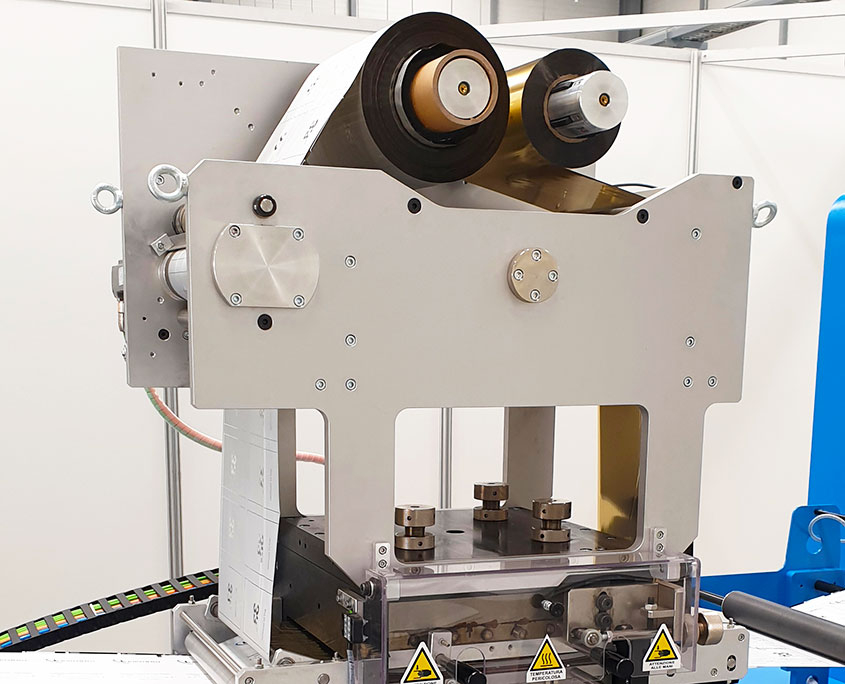

UNWINDER

- Servo driven with max. Ø 700 mm (27,5”), ID 76mm (3″)

- Automatic stop at master roll end with programmable roll-end settings

- Clockwise/counterclockwise unwinding

- Electronic web guide system with ultrasonic sensor and splice table with pneumatic clamps

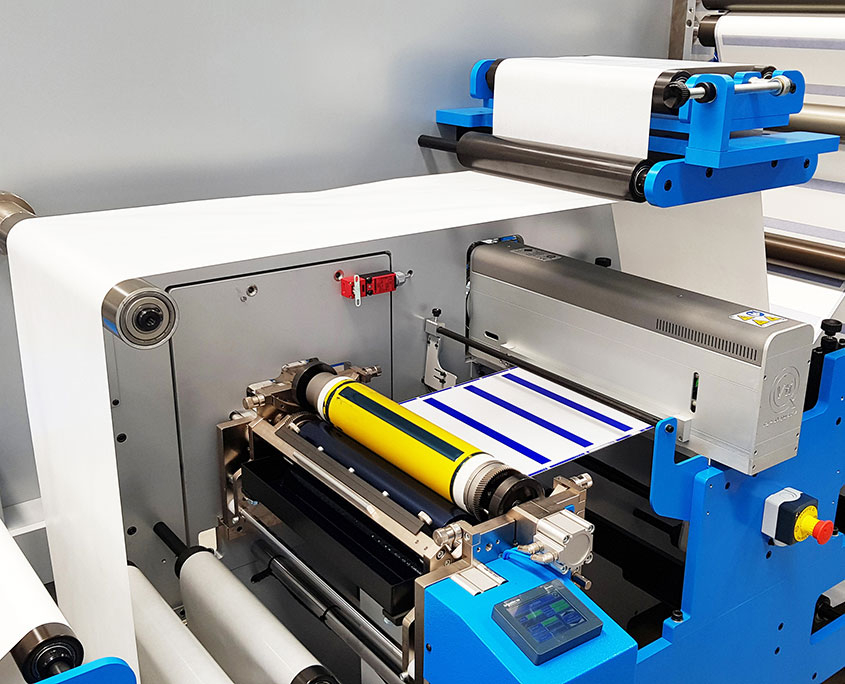

DIE CUTTING

- Operates in full Rotary or Semi-rotary modes

- Die repeats in Rotary Mode: min. 203,20 mm (8″) – max. 431,80 mm (17″)

- Recommended die repeat in Semi-Rotary Mode (magnetic cylinder included Z130 1/8″): 82,55- 330,20 mm (3,25 – 13″)

- Servo driven buffer

- Deflation function for existing flexible dies in semi-rotary mode

- Easy Strip waste rewinder max. Ø 600mm (24”)

DIE CUTTING EQUIPPED WITH SPEED PACK (OPTIONAL)

- Maximum semi-rotary speed 80 m/min. – speed may vary depending on plate size

- Die repeats in Rotary Mode: min. 203,20 mm (8″) – max. 603,25 mm (23.75”)

- Recommended die repeat in Semi-Rotary Mode (magnetic cylinder included Z190 1/8″) 120,65 – 482,60 mm (4,75 – 19”)

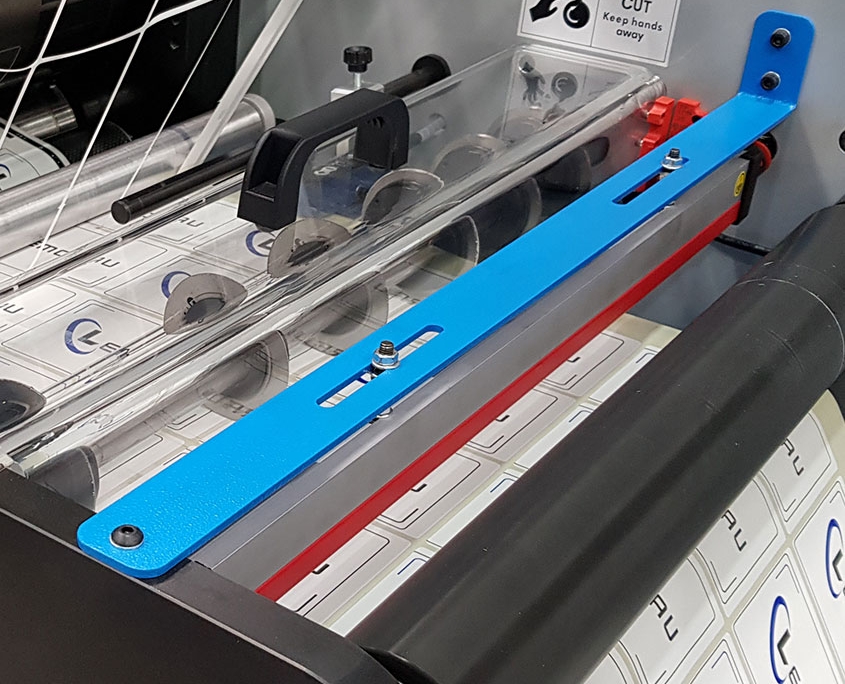

SLITTING UNIT

- Cassette system equipped with 6 sets of circular knives with lateral adjustment

- Air Trim Removal

REWINDING

- Servo driven equipped with 2 interchangeable pneumatic rewinders, ID 76mm (3″)

- Semi-automatic rewinding

- Clockwise/counterclockwise rewinding (labels in/ labels out)

- Max. rewinder Ø 580 mm (23“) using single rewinder / 350mm (14“) using double rewinder

OPTIONAL EQUIPMENT

- Additional mandrels in customized sizes

- Additional die station

- Additional slitting knives

- Anti-static bar

- Anvil roll with adjustable gap

- Automatic die mounting/ removal

- Automatic lubrication system

- Automatic slitting with gap measurement sensor

- Back scorer unit- manual/ automatic

- Bearer wipers & lubrication

- Booklet label module

- Clear on clear sensor

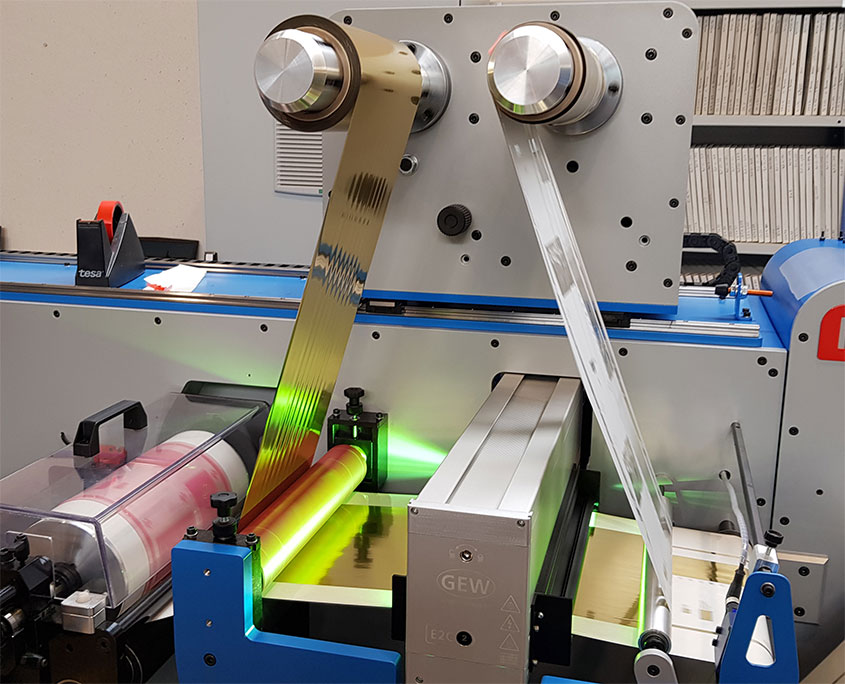

- Cold foil – full rotary or semi-rotary

- Corona treatment

- Custom die cutting unit according to existing cylinders

- Delam/Relam – rotary mode

- Digital embellishment module

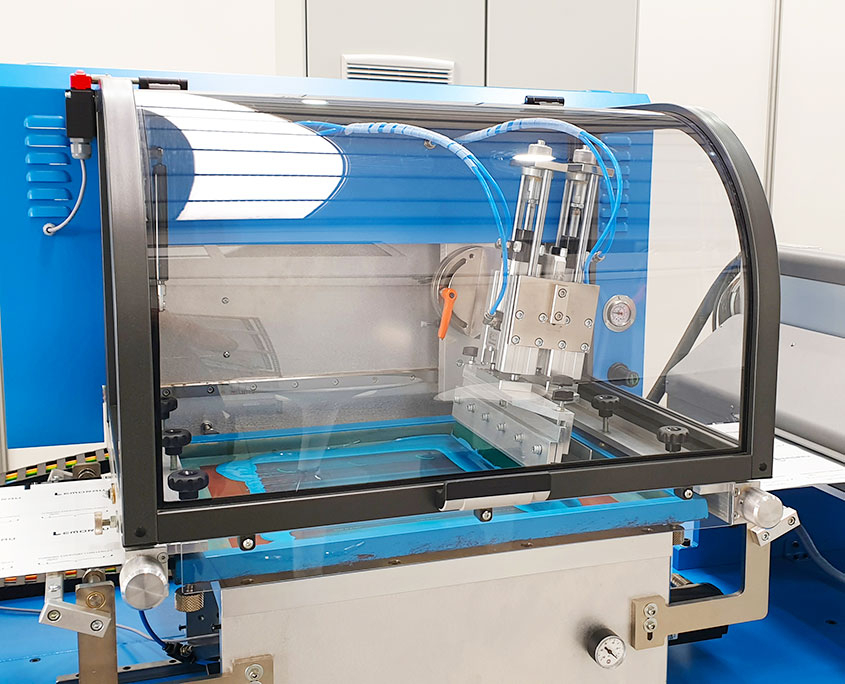

- Flat bed screen printing

- Flexo units – Semi-rotary/Rotary

- Flexo printing presses

- Hot foil flat bed

- Inkjet module for variable data

- Lamination station (self wound with liner)

- Laser cut

- Modular unwinder Ø 1meter (40″)

- Multi layer – crossover or lamination in register

- Non stop buffer for continuous run

- Pressure gauges for die cutting unit

- QR code reader for an automatic set up

- Razor slitting knives

- RFID and NFC Tag application

- Smart sheeter & conveyor for sheet label production

- Speed Pack Semi-rotary die cut up to 80m/min.

- Super Speed Pack for semi-rotary – over 100m/min.

- Turn bar – fixed or movable

- Turret rewinding – semi-automatic with gap stop position

- Web cleaner